Rockwool has emerged as a game-changing material in the construction and insulation industries, offering unparalleled benefits for energy efficiency, soundproofing, and fire resistance. As the demand for sustainable and environmentally friendly solutions grows, this mineral wool product has gained widespread recognition for its performance and versatility. Whether you're a contractor, homeowner, or architect, rockwool is a choice that aligns with modern building standards and environmental goals.

Made from natural volcanic rock and recycled slag, rockwool is celebrated for its eco-friendly production process and outstanding thermal and acoustic properties. Its unique composition allows it to withstand high temperatures, resist moisture, and maintain its structure over time, making it an ideal insulation material for both residential and commercial projects. With its ability to reduce energy consumption and improve indoor air quality, rockwool is more than just insulation—it's a step toward a greener future.

In this comprehensive guide, we’ll delve into everything you need to know about rockwool, from its origins and manufacturing process to its applications and benefits. We’ll also cover key considerations for installation, environmental impact, and frequently asked questions to provide a complete understanding of why rockwool is a smart choice for your next building project.

Table of Contents

- What is Rockwool?

- History and Origin

- How Rockwool is Made

- Key Properties of Rockwool

- Rockwool vs. Other Insulation Materials

- Applications of Rockwool

- Benefits of Using Rockwool

- Installation and Maintenance

- Fire Resistance and Safety

- Environmental Impact and Sustainability

- Cost Efficiency and Value

- Common Misconceptions About Rockwool

- FAQ About Rockwool

- Conclusion

What is Rockwool?

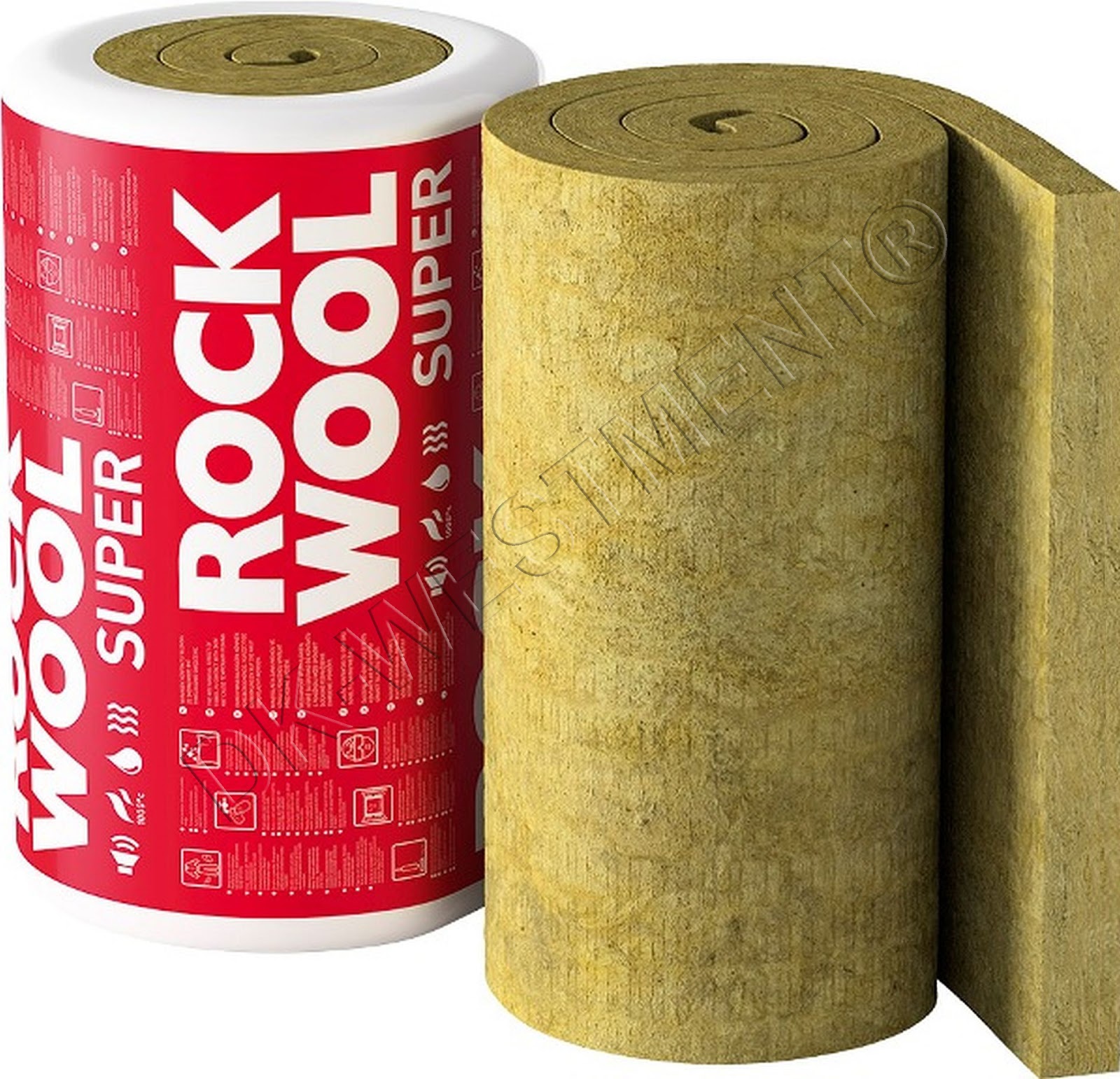

Rockwool, also known as stone wool, is a type of mineral wool insulation made from natural rock and recycled materials. It is manufactured by melting volcanic rock, such as basalt, and spinning it into thin fibers, creating a dense and durable material with exceptional insulating properties. Unlike traditional insulation materials, rockwool is non-combustible, highly resistant to moisture, and offers superior soundproofing capabilities.

The primary components of rockwool include basalt rock and slag, a byproduct of steel manufacturing. These raw materials are melted at temperatures exceeding 1,400°C (2,552°F) and then spun into fibers. The resulting material is compressed and bonded into various forms such as rolls, boards, or loose-fill insulation. Thanks to its unique composition, rockwool is not only effective but also environmentally sustainable, as it incorporates recycled materials and supports energy conservation.

Rockwool is widely used in residential, commercial, and industrial settings for insulation, soundproofing, and fireproofing. Its versatility and durability make it a popular choice for walls, roofs, floors, and even industrial piping. With increasing emphasis on energy efficiency and sustainability, rockwool has become a cornerstone material in modern construction practices.

History and Origin

The story of rockwool dates back to the early 20th century when it was first discovered as a byproduct of volcanic activity. The natural process of molten lava cooling and spinning into fibers inspired scientists and engineers to replicate the phenomenon in a controlled environment. In 1937, the Rockwool Group was established in Denmark, marking the beginning of large-scale production and commercialization of this innovative material.

Over the decades, rockwool has evolved from a niche product to a globally recognized solution for insulation and energy efficiency. Its development was driven by the need for sustainable building materials that could address challenges such as energy loss, noise pollution, and fire hazards. Today, rockwool is manufactured worldwide and continues to set benchmarks for performance and sustainability in the construction industry.

The adoption of rockwool has been particularly strong in regions with stringent building codes and environmental regulations. Europe, North America, and Asia are among the leading markets, with applications ranging from residential homes to large-scale industrial facilities. The material's ability to adapt to diverse climatic and structural conditions has further cemented its reputation as a reliable and versatile choice for builders and engineers.

How Rockwool is Made

The manufacturing process of rockwool is a fascinating blend of natural resources and advanced technology. It begins with the selection of raw materials, primarily basalt rock and recycled slag. These materials are melted in a high-temperature furnace, reaching over 1,400°C (2,552°F). The molten rock is then spun into fine fibers using a spinning wheel or a stream of compressed air.

Once the fibers are formed, they are treated with a binding agent and compressed into sheets, rolls, or loose-fill insulation. The material is then cured in an oven to set its shape and enhance its structural integrity. Depending on the intended application, rockwool can be cut into various sizes and shapes or coated with additional layers for specific properties like water repellency or increased durability.

One of the standout features of rockwool production is its commitment to sustainability. The use of recycled slag not only minimizes waste but also reduces the reliance on natural resources. Additionally, the production process is designed to minimize energy consumption and emissions, aligning with global efforts to combat climate change.

Overall, the meticulous manufacturing process ensures that rockwool meets the highest standards of quality and performance. Each batch undergoes rigorous testing to verify its thermal, acoustic, and fire-resistant properties, making it a trusted choice for a wide range of applications.

Key Properties of Rockwool

Rockwool stands out for its unique combination of properties that make it an ideal insulation material. These include:

- Thermal Insulation: Rockwool has a low thermal conductivity, effectively reducing heat transfer and maintaining indoor temperatures.

- Soundproofing: The dense structure of rockwool fibers absorbs sound waves, minimizing noise pollution.

- Fire Resistance: Rockwool is non-combustible and can withstand temperatures up to 1,800°F (982°C), providing critical fire protection.

- Moisture Resistance: Rockwool is hydrophobic, meaning it repels water and resists mold and mildew growth.

- Durability: Unlike organic insulation materials, rockwool does not degrade over time, ensuring long-lasting performance.

These properties make rockwool a versatile and reliable choice for a wide range of applications, from residential homes to industrial facilities. Its ability to address multiple challenges—thermal inefficiency, noise pollution, and fire hazards—sets it apart from other insulation materials.

Rockwool vs. Other Insulation Materials

When choosing insulation, it’s essential to understand how rockwool compares to other materials like fiberglass, foam, and cellulose. Each material has its advantages and drawbacks, but rockwool offers a unique blend of benefits that often make it the superior choice.

Thermal Performance: While fiberglass and foam are effective insulators, rockwool's denser structure provides better thermal performance, particularly in extreme climates.

Fire Resistance: Unlike foam insulation, which can release toxic fumes when burned, rockwool remains stable and non-combustible, making it a safer option for fire-prone areas.

Soundproofing: The acoustic properties of rockwool far exceed those of fiberglass and cellulose, making it ideal for applications where noise reduction is a priority.

Environmental Impact: Rockwool's use of recycled materials and its recyclable nature make it more eco-friendly than foam or fiberglass, which rely heavily on synthetic components.

Overall, rockwool's versatility and superior performance often outweigh its slightly higher upfront cost, making it a worthwhile investment for long-term benefits.

Article Recommendations

- Gabby Sidibe Net Worth 2024 A Deep Dive Into Her Life Career And Wealth

- Mastering Shohei Ohtani Muscle The Science Behind His Athletic Prowess

- Musk Kids Name A Closer Look At Elon Musks Unique Family